INNOVATORS

OF THE MOISTURE DRILLING SYSTEM®

AND

WASTEWATER TREATMENT TECHNOLOGY SCANPOL®

Company Products

-

The following products you may purchase from us:

Moisture

Drilling System®

-

What is Moisture Drilling?

QUALITY

Moisture

drilling reduces friction on the drill, thereby considerably enhancing

its cutting effect:

- Cleaner

cutting of glass fibre bundles

- significantly

reduce nail heading

- less

resin smear

- less

pink ring

- smooth

hole walls

PRODUCTIVITY

The productivity

of a drilling machine depends primarily on the stack height of circuit

boards. With moisture drilling the stack height can be increased

by up to 100% The

”lubricating” chemistry effect, obtained with Cutting Related

Solution 9106 substantially reduces registration deviation from

true centre when drilling through high stacks. The drill remains

precisely positioned, allowing throughtout higher stacks to be

processed.

REDUCED

WEAR ON DRILL

The cooling

and lubrication provided by moisture drilling result in even wear

on the drill:

- little

or no edge breaking

- even

wear on cutting edge

- less

grinding required when resharpening

- greater

number of resharpenings possible

AN

OUTLINE OF ITS MANY ADVANTAGES

IMPROVED

HOLE WALL QUALITY

- smooth

hole walls

- less

smear

- excellent

drilling registration

- less

nail heading

PLEXIGLAS

DRILLING

- doubled

infeed rate

- swarf

free small holes

- added

dimensional stability

SPECIAL

MATERIALS WHICH BECOME EASIER TO DRILL

- plexiglas

- polyimide

- teflon

- metal

core, thermal clad

- back

planes

TOP

SCANPOL® PRODUCTS FOR WASTEWATER TREATMENT

Industrial

Wastes

Industry production processes create a variety of wastewater pollutants,

some that are difficult and/or costly to treat. Waste water characteristics

and levels of pollutants vary significantly by industry. Additionally,

fluctuations may occur in the waste water's daily and hourly flow,

temperature and composition. In some instances, several waste

streams from different processes at an industry location may discharge

at the same location.

Discharges from industrial facilities can be direct or indirect.

Direct discharges are made directly to a waterway or water body.

Indirect discharges are usually made to Publicly Owned Treatment

Plants (POTWs), and the discharge is treated by the POTW. Additionally,

some facilities participate in source control that utilizes water

reuse, waste minimization or pollution prevention to reduce or

eliminate discharges of pollutants.

Conventional cleaning technology

Metal hydroxide precipitation is the standard method for removing

harmful metals from metal finishing waste water. This is achieved

by adjusting the pH of the waste water with an alkaline reagent

to deposit the dissolved metals and settle and remove the resultant

metal hydroxide precipitates. This procedure usually needs pre-treatment

prior to metals precipitation, such as the oxidation of cyanide

(CN-) or reduction of chromium hexavalent (Cr6+), to deal with

substances that interfere with the precipitation.

Nucleation agents are also used to enhance the settling of fine

precipitates. The use of nucleation enhances the performance of

the cleaning procedure so that the metal concentration in effluents

after purification is characteristically one order of magnitude

lower than after treatment without added nucleation agents . Nucleation

agents can be a co-precipitated metals such as iron that is added

as the sulphate/chloride salt to provide co-precipitation with

ferric hydroxides. An excess of co-precipitation metal also masks,

to some degree, complexing agents present in waste waters.

SCANPOL® treatment technology

SCANPOL® products are developed in the line of Swedish environmental

law that is forcing development of chemicals that have lowest

impact on the environment. Therefore our developed SCANPOL® products

for wastewater treatment are principally base on inorganic chemistry.SCANPOL®products has been developed especially for the treatment

of spent rinse water, half concentrates and concentrates from

Metal Finishing, PCB and painting industries and Energy Sector.

SCANPOL®products precipitates contaminations and heavy metals

from the solutions. It is especially adopted for the treatment

of spent solutions when low discharge of heavy metals, phosphates

and fluorides is demanded. The most suitable way to control the

treatment is in proportion to the flow. It is very suitable for

a through flow or a batch treatment plant.

The precipitated metals form stable flocks which settles very

rapidly and are easy to separate. The clear decant contains a

very small amount of suspended solids and the COD, phosphorus

and fluoride content is significantly reduced.

| SCANPOL® 20 |

WWT

reduction of heavy metals, P,F,COD |

| SCANPOL® 27 |

WWT

reduction of heavy metals, P,F,COD |

| SCANPOL® 31 |

WWT

reduction of heavy metals, P,F,COD |

| SCANPOL® 40 |

WWT

reduction of heavy metals, P, F, COD

|

| SCANPOL® 51 |

WWT

flocculant |

| SCANPOL® 54 |

WWT

flocculant |

| SCANPOL® 55 |

WWT

flocculant |

SCANPOL® 87

|

WWT

reduction of heavy metals, P,F, COD |

| SCANPOL® 216 |

WWT

reduction of heavy metals and COD |

Download additional information above SCANPOL® products

TOP

|

Control

box for MDS

Control

box for MDS

Separator

for MDS

Separator

for MDS

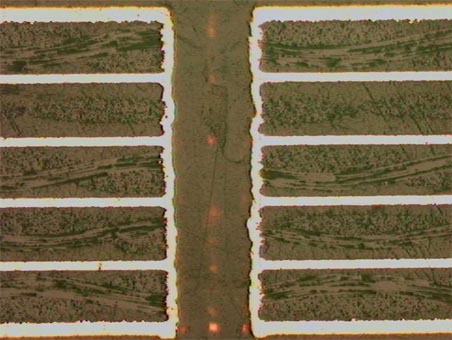

Cross

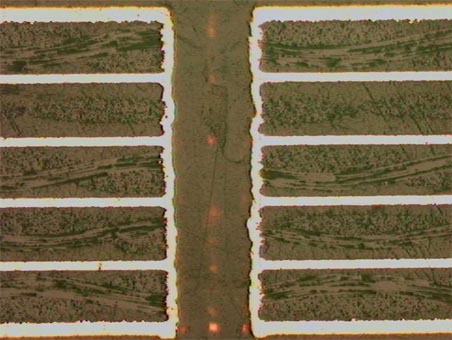

section of hole drilled with MDS 0.35 mm 10000 hits, 2 panels

in stack

Cros section of hole dry drilled 0,35 mm 10000

hits, 2 panels in stack

HIGHER

THROUGHPUT

- especially

when drilling small holes

- for

double sided PCB 25-50%

- for

multilayer PBC 33-100%

IMPROVED

EFFICIENCY

- increased

throughput per machine

- longer

drill bit life

- less

entry and back-up material usage

- standard

back taper drills can be used for multilayer boards

SCANPOL® 27

This product may be used at treatment of spent solutions when low discharge of phosphate, fluoride and heavy metals is demanded. Product needs to be continuously stirred during dosing to normalisation step at pH 2,0-2,5. When treating liquids containing traces of hexavalent chromium, Cr+6 is reduced to Cr+3 even in an alkaline medium. The pH of SCANPOL 27 is slightly acidic 1,3-3,0.

SCANPOL® 30

This product should be used when demands for low discharge of heavy metals and phosphate is expected. This product gives lower amount of sludge in comparison with standard iron chloride/ calcium chloride method. Product is delivered as ready to use solution and is acidic.

SCANPOL® 40

This product should be used when demands for low discharge of heavy metals, fluoride and phosphate is expected. This product gives lower amount of sludge in comparison with standard iron chloride/ calcium chloride method. Product is delivered as ready to use solution and is acidic.

SCANPOL® 51, 54, 55

Those products are mainly acryl amid polymers and are used as help to coagulate achieved precipitation. Products are powders and should be used as 0,05-0,1% water solution. Which of those product give optimal coagulation have to be find by laboratory trials.

SCANPOL® 87

With help of this product wastewater may be treated if low content of heavy metals, phosphor and COD is demanded. If heavy metals need high precipitation pH, please use SCANPOL® 40 as precipitation aid. SCANPOL® 87 is delivered as ready to use solution and is acidic.

SCANPOL® PRODUCTS AND APPLICATION

Comparison

of sludge volume at the same dosing ratio of FeCL3 and SCANPOL® products

FeCL3 SP®40 SP® 27 FeCL3 SP®40 SP® 27

Rinse

water after ammonia etch treated with SCANPOL® 27

|

FeCL3 SP®40 SP® 27

FeCL3 SP®40 SP® 27